The Indiana Army National Guard, in collaboration with the Office of the Under Secretary of Defense for Research and Engineering, achieved a historic milestone during August's Technology and Readiness Experimentation 25-2 exercise, successfully conducting a first of its kind demonstration of tactical in-flight 3D printing aboard a U.S. Army UH-60 Black Hawk helicopter.

The demonstration showcased the FieldFab Expeditionary 3D Printer, a ruggedized additive manufacturing system designed by Craitor Inc. of San Diego, California, to withstand expeditionary conditions and operate under MIL-STD-810H standards for survivability during ground vehicle transportation, through shock and vibration experienced during transport, and in extreme hot/cold temperatures.

“This demonstration is about more than printing parts in the air—it’s about transforming how the military can sustain combat power,” said Eric Shnell, CEO of Craitor. “If soldiers can fabricate precision components on-demand, even while airborne, it means less downtime, greater readiness and unmatched adaptability in contested environments.”

Securely mounted inside the aircraft and powered by Sentient Industries’ METEOR Quiet Tactical Power solution, the system printed attritable unmanned aerial system parts to stringent original equipment manufacturer specifications, all while the aircraft executed maximum performance tactical maneuvers at altitude. The printer fabricated components from a standardized technical data package, underscoring how additive manufacturing can integrate into the Defense Industrial Base’s digital engineering and sustainment ecosystem.

A Leap Forward in DoD Priorities

The achievement comes as the Department of Defense accelerates innovation under the direction of Secretary of Defense Pete Hegseth’s recent memorandums, including the July 10, 2025 ‘Unleashing U.S. Military Drone Dominance’ and the April 30, 2025 ‘Army Transformation and Acquisition Reform’ directives. These policies emphasize empowering warfighters to procure and adapt drones independently, while also calling for operational units to employ additive manufacturing technologies by 2026.

By producing UAS components in-flight, the Indiana National Guard demonstration directly aligns with these priorities, pushing the boundaries of how distributed manufacturing can support attritable systems production and rapid mission adaptation in theater.

T-REX 25-2: Innovation at the Edge

The experimentation exercise at Camp Atterbury and Franklin, Indiana, brought together soldiers, researchers and industry partners to stress-test emerging technologies against real-world threats.

This year’s focus areas included Passive Multispectral Air Surveillance Kill Chain, counter-UAS systems, Low-Cost Short Range Air Defense solutions, and One-Way Attack platforms.

The in-flight 3D printing demonstration was a standout example of how tactical experimentation can directly inform senior leader decision-making, shaping future investments and accelerating the adoption of capabilities that strengthen deterrence.

"This is exactly what T-REX was designed for,” said Lt. Col. Matthew Limeberry, the Rapid Assessment of Prototype Technology Readiness Task Force commander. “We are moving promising technologies out of the lab and into the hands of soldiers—assesing how they perform under operational conditions and how they can transform the fight. Innovation like this highlights how quickly we can adapt commercial technologies to operational realities. The ability to print parts mid-mission represents a new level of agility for sustainment and expands what our forces can achieve under fire.”

Implications for the Future Force

The Indiana National Guard’s successful trial represents a pioneering step toward mobile, distributed manufacturing for expeditionary operations. Rather than relying solely on long supply chains, forces could soon design and produce replacement parts, adaptive drone payloads, and mission-specific equipment closer to the tactical edge.

By proving that additive manufacturing can function under the extreme vibration and dynamic conditions of rotary-wing flight, the demonstration sets the stage for a future where warfighters no longer depend on long, vulnerable supply chains, but instead carry the means of production with them.

Indiana's state parks offer New Years Day events

Indiana's state parks offer New Years Day events

Indiana casinos see revenue dip in November

Indiana casinos see revenue dip in November

City interested in purchasing land for second downtown parking garage

City interested in purchasing land for second downtown parking garage

Knauf Insulation to become first fiberglass insulation manufacturer formaldehyde free by end of 2025

Knauf Insulation to become first fiberglass insulation manufacturer formaldehyde free by end of 2025

Site development plans approved for Speedway, Circle K

Site development plans approved for Speedway, Circle K

ISP shopping safety tips

ISP shopping safety tips

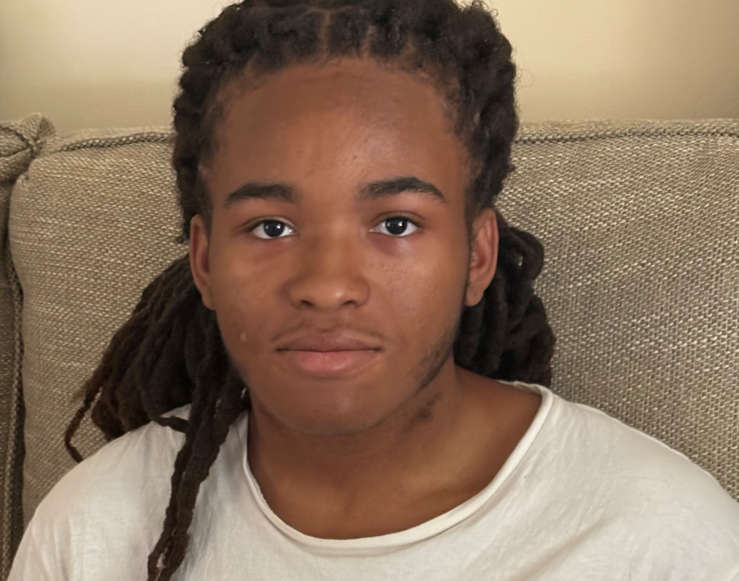

Silver Alert declared for missing Indianapolis teen

Silver Alert declared for missing Indianapolis teen

Hope and Rushville awarded OCRA grants

Hope and Rushville awarded OCRA grants