Local manufacturer American Container continues to expand its capacity. The Plymouth-based company that manufactures corrugated paper and plastic products was granted a business personal property tax abatement Monday night. American Container will be investing in a new machine that will print, cut, glue, and fold boxes all in one operation. All in shorter make-ready time, and with tighter tolerances to meet customer requirements.

American Container produces corrugated boxes, corrugated plastic boxes, door fillers, and load securement products. They have been working in the pharmaceutical industry to provide packaging solutions that meet the industry’s high standards for several years. The $5.8M investment will be a line that will allow American Containers to continue to provide these solutions and pursue additional customers not only in the pharmaceutical industry, but other demanding industries.

The Plymouth City Council approved a five-year phased-in tax abatement for the capital expenditure. The increase in efficiency and additional capacity will help retain 73 employees currently working in Plymouth. This additional equipment will conservatively create two additional positions, with the possibility of others as the new line of product brings additional demand.

A phased-in tax abatement allows the manufacturer to gradually add the additional assessed value of the property onto their taxable property. Instead of a large increase in taxes the first year the equipment is put into service, the value of the equipment can be added incrementally over the term of the abatement.

The tax abatement doesn’t decrease the amount of taxes the manufacturer pays from the previous year; it just delays the increased amount they will pay over the next several years because of the investment in new equipment.

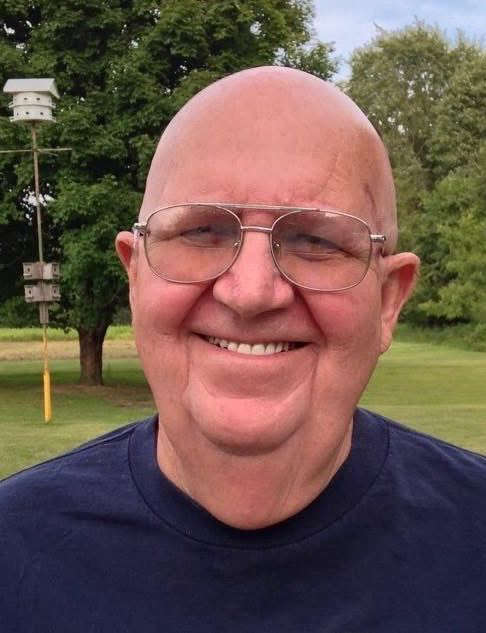

“Helping industry to expand and retain their current workforce is more important than ever,” said Greg Hildebrand, President/CEO of Marshall County Economic Development Corporation. “Incentivizing our current industry to invest in equipment that will increase efficiency and keep current employees learning new skills will ultimately lead to higher wages.”

“American Container and the Isban family have contributed greatly to the local communities. Having their headquarters remain here is beneficial to the local economy and speaks volumes about the continually improving quality of life,” Hildebrand added.

It is expected that the new equipment can be delivered and installed to be productive sometime in the first quarter of 2026. Currently, American Container has a similar unit at its California facility that can help make the training and initial setup an easier process.

ISP Commercial Vehicle Enforcement Division Statistics

ISP Commercial Vehicle Enforcement Division Statistics

IN Reps. Jordan & Teska to appear at Third House Wednesday with Senator Bohacek

IN Reps. Jordan & Teska to appear at Third House Wednesday with Senator Bohacek

City Police arrest two in separate incidents Monday and Tuesday

City Police arrest two in separate incidents Monday and Tuesday

IN Rep. Jack Jordan: New study highlights Indiana's progress in career readiness

IN Rep. Jack Jordan: New study highlights Indiana's progress in career readiness

Indiana is Open for Business: February’s Jobs and Wages Wins

Indiana is Open for Business: February’s Jobs and Wages Wins

Plymouth Mayor announces Free Summer Concert Series Lineup

Plymouth Mayor announces Free Summer Concert Series Lineup

Risen movie March Seasoned Citizen Matinee at The REES

Risen movie March Seasoned Citizen Matinee at The REES

U.S. Senator Young: Resolution Recognizing CTE Month passes senate

U.S. Senator Young: Resolution Recognizing CTE Month passes senate